What factors should be considered in the selection of polishing cloth wheel?

- 发布日期 : 2020-08-21

- 阅读量 : 23

What factors should be considered in the selection of polishing cloth wheel?

The linear speed of polishing cloth wheel and whether the polishing cloth wheel can achieve the polishing effect required by the workpiece are the primary considerations when we choose polishing Bren. The best polishing effect can be achieved only when the polishing cloth wheel is selected reasonably.

There are many factors in the selection of polishing cloth wheel

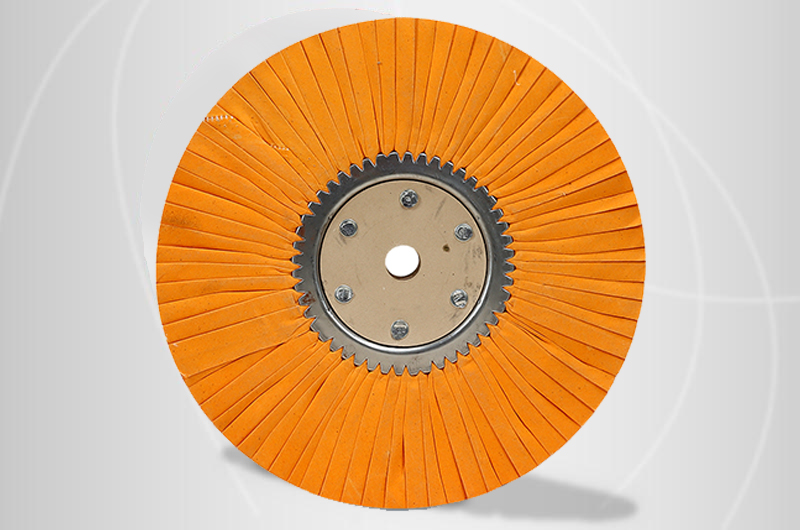

1、 Types of polishing cloth wheel

1. Twill cloth wheel

A kind of polishing wheel, which is generally suitable to be sewn by spiral method. Due to its high application requirements, the manufacturer considers the quality problem most when producing this kind of polishing wheel. Generally, the material selection is exquisite and the workmanship is regular, so the price is high.

Whether the wheel body material (fiber) and polishing wax component (grease) can be in good contact is directly related to the adhesion of polishing wax. The better the adhesion, the better the polishing and cutting effect, and the less times of wax coating. For specific data and parameters, please refer to the instructions of different specifications of polishing wheel factory.

2. Oil immersed twill cloth wheel

Its internal fiber has been immersed in the component of polishing wax grease, which makes it have a very high polishing effect at the beginning. The grease impregnated into the wheel plays a lubricating role in the friction between the cloth inside the cloth wheel, reduces the imperceptible damage to the minimum degree, and has a longer service life. Under laboratory conditions, the cutting effect of the oil immersed polishing wheel is better than that of the polishing wheel without oil immersion treatment on any material, and its service life is increased by 30%. The special design can also improve the ventilation effect and meet the needs of rapid cutting of various metals. It has many advantages, such as fast cutting ability, long wear-resistant life, slight heating, etc. For specific data and parameters, please refer to the instructions of different specifications of polishing wheel factory.

3. Crease wheel

The air can circulate freely and the cooling effect is good. For specific data and parameters, please refer to the instructions of different specifications of polishing wheel factory.

4. Cloth wheel and hemp wheel

The main differences are: cloth wheel is mainly used to obtain high plane and mirror effect; hemp wheel is mainly used for rough throwing and medium throwing. The final effect is related to the type, performance and workpiece material of polishing wax.

2、 Material of workpiece to be thrown

Generally, we divide the materials of the workpiece to be thrown into two categories, one is metal, the other is non-metallic, and the other is ferrous metal, including iron, stainless steel, alloy steel, carbon steel, etc. One is non-ferrous metals, including copper, brass, bronze, zinc, aluminum, nickel, etc. And non-metallic category, including: plastic, painting, wood, stone and so on. When the material of the workpiece to be polished is different, the types of cloth wheel are different. The basic selection method is to consider the surface hardness of the workpiece to be polished. For example, the surface hardness of the iron metal is higher, so the hemp wheel is often selected to achieve the cutting effect. If the non-ferrous metal is also used, the polishing mark on the surface is relatively thick, which is not accepted by customers For non-ferrous metals, we mostly use cotton wheel to polish.

Special materials, such as gold, platinum and other precious metals, chromium, nickel coating metal, hard plastic, etc., are recommended to ask for professional guidance to prevent any unexpected loss.

3、 Sanding times of previous works

The number of times of sanding in the previous project will directly affect the selection of cloth wheel, slurry or paste for polishing operation. If it is not selected properly, it will cause unnecessary cost waste. The adjustment and collocation are also very important. Users must understand the characteristics and components of polishing materials, otherwise the best polishing materials will be used in inappropriate places, It can not achieve the desired effect.

4、 Types of polishing equipment

Automatic polishing machine and manual polishing machine, the basic method of selecting cloth wheel is different. The main reason is that the polished workpiece of automatic polishing machine is fixed on the fixture, and the polished workpiece is moved into and contacted by the cloth wheel shaft group to achieve polishing action, or the polished workpiece is fixed on the fixture and enters into the side or bottom of the cloth wheel shaft group through a conveyor belt to contact with it to achieve polishing action In other words, the basic form of cloth wheel is almost completely different for different types of polishing machines.

5、 According to the shape of the workpiece to be thrown

After the type of polishing machine and the shape of the workpiece to be polished are confirmed, the selection of cloth wheel can be roughly determined. Generally, for plane workpiece, the more rigid cloth wheel is selected, and then the contact pressure is added according to the rotation speed of the machine, and then some adjustment is made. However, for the workpiece with large drop and complicated shape and profile, the selection of cloth wheel is better For the soft and elastic cloth wheel, on the manual polishing machine, the cloth wheel with elastic contact surface and hard base is selected. We need to choose the appropriate Bren according to the material of polishing, so as to achieve the highest efficiency of polishing, and achieve twice the result with half the effort.

Factors affecting the linear speed of polishing cloth wheel: the first point is the rotational speed, that is, how many revolutions per minute. The second point is the surface linear velocity, which is how many meters per minute. The line speed affects the polishing effect, 3600-7500 is suitable, the higher the line speed, the better the effect.

The processing process of workpieces under the action of polishing cloth wheel generally includes: rough polishing, medium polishing and fine polishing. For a brief introduction: rough polishing, using coarse materials such as corundum, derusting and scratch spots to form polishing cloth wheel; medium polishing,

For polishing plane workpieces, more rigid cloth wheels are selected, and then the contact pressure is added according to the speed of the machine, and then some adjustments are made. However, for the workpiece to be polished with large drop and complex shape and profile, the cloth with soft and elastic surface is selected for automatic polishing machine, while for manual polishing machine, cloth with elastic contact surface and very hard base is selected for polishing Wheel. We need to choose the appropriate Bren according to the material of polishing, so as to achieve the highest efficiency of polishing, and achieve twice the result with half the effort.

Factors affecting the linear speed of polishing cloth wheel: the first point is the rotational speed, that is, how many revolutions per minute. The second point is the surface linear velocity, which is how many meters per minute. The line speed affects the polishing effect, 3600-7500 is suitable, the higher the line speed, the better the effect.

The processing process of workpieces under the action of polishing cloth wheel generally includes: rough polishing, medium polishing and fine polishing. Brief introduction: rough polishing, using coarse materials, such as corundum, rust removal, scratch spot rough processing into polishing cloth wheel; intermediate polishing, generally using sharp cutting materials, for stainless steel, etc., to remove the surplus part of the surface, so as to obtain quite good luster; Polishing, using soft and qualified polishing wax is the metal material to show the original luster. Most polishing parts need several polishing processes, and several different types of polishing cloth wheels are commonly used to achieve the ideal polishing effect.

The above polishing wheel manufacturers sort out and summarize the selection factors of polishing cloth wheel, hoping to help you.

返回列表

返回列表