Six steps of workpiece polishing in mechanical polishing technology

- 发布日期 : 2020-08-21

- 阅读量 : 24

Six steps of workpiece polishing in mechanical polishing technology

Want to do a good job in polishing the workpiece? The six steps you have to do well. What we want to show you today is the mechanical polishing technology.

Mechanical polishing is commonly used in metal surface treatment technology. It uses flexible polishing tools and abrasive particles to modify the surface of the workpiece. A very thin layer of metal on the grinding surface of the sample is removed by grinding and rolling with very fine polishing powder. The Ra value after polishing can reach 1.6 ~ 0.008 mm with different pre-processing conditions.

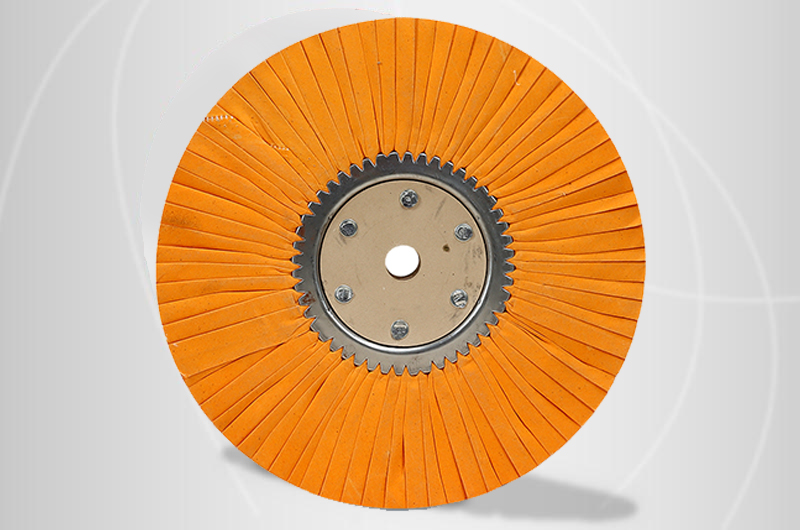

The purpose of polishing is to obtain a smooth surface or specular gloss, sometimes to eliminate gloss (extinction). Generally, polishing wheel is used as polishing tool. When polishing, the high-speed rotating polishing wheel (with a circumferential speed of more than 20 m / s) presses the workpiece, which makes the abrasive roll and micro cut the surface of the workpiece, so as to obtain a bright machined surface, and the surface roughness can reach ra0.63-0.01 μ m generally. When the non greasy Matt polishing agent is used, the bright surface can be dulled to improve the appearance.

The polishing process is divided into six steps

Rough polishing is mainly suitable for the situation of low requirements on the surface of the product. By placing the abrasive and the product in the drum, the product and abrasive can roll randomly in the cylinder to achieve the purpose of reducing the surface roughness.

Fine casting is divided into semi precision casting and fine casting.

Sandpaper and kerosene are mainly used in semi fine polishing. The number of sandpaper is: ා400 ~ ාා600 ~ ා800 ~ ා1000 ~ ා1200 ~ ා1500). In fact, the

In fine polishing, the polishing roll is mainly used, and the usual grinding sequence is 9 μ m (1800 μ m) → 6 μ m (3000 μ m) → 3 μ m (8000 μ m). The 9 μ m polishing roll is used to remove the hairlike wear marks left by the 1200 ᦇ and 1500 ා sandpaper. Then polish with 1 μ m (14000 ා). After polishing, the surface roughness can reach ra0.01 μ m, and no surface defects can be observed under a 40 times magnification microscope.

In addition, the working environment of polishing is also very important. Whether the polishing can reach the standard depends on the polishing environment. Make sure that the working procedures are separated, otherwise polishing problems may occur.

返回列表

返回列表